Robotics in the Pharmaceutical and Life Sciences Industry

Robotics deals with the design, construction, operation, and application of robots coupled with computer systems for their control, sensory feedback, and information processing. Very often the design of a given robotic system brings together principles of electronic engineering, mechanical engineering and computer science (artificial intelligence in particular). Since the turn of the 20th century, research into the functionality and potential uses of robots has seen a lot of action. Given the rapid pace of technological advances, the research, design, and building of new robots have begun to serve various practical purposes – domestically, commercially and militarily. Today, many robots do jobs that are hazardous to people such as defusing bombs, mines and exploring shipwrecks. We spoke to a few people who are working with robots both academically and commercially in India and got to know their thoughts on the growing field of Robotics, the burgeoning opportunities that have opened up as well as the many challenges that they face in an Indian scenario.

Opportunities in Robotics in India

Dr. Bijay Kumar Rout, Associate Professor, Department of Mechanical Engineering, Coordinator Center for Robotics and Intelligent Systems, BITS, Pilani

Robotics opens up a plethora of opportunities for both entrepreneurs and students. Talking about them, Dr. Bijay Kumar Rout, Associate Professor in the Department of Mechanical Engineering, Coordinator Center for Robotics and Intelligent Systems, BITS Pilani says that industries across a range of sectors such as automotive, atomic energy, defence, space, metals, textiles and manufacturing use Robotic technologies very extensively. He further adds, “robots are required everywhere to improve productivity. They are also being used in operation theatres and rehabilitation centres to augment the quality of life. Developed countries like Japan and America have been using robots to clean rooms, entertain etc. It is an ever growing field and many avenues have opened up in recent past. Therefore students who have the required skill sets will be favoured by such industries.” He further adds that, “the automation industry is a big consumer of Robotic technology. Using such technology, the quality of products and processes improve considerably.”

Abheek Bose, CEO, Robots Alive, a Bangalore-based company founded in 2009 that designs cost effective robotic & automation systems for the SME sector has this to say to those who wish to make a career in Robotics – “It is a multidisciplinary engineering field. One gets to understand the integration of mechanical, electrical, electronics as well as computer science disciplines in this field. Depending on the focus area, they can move on to various engineering domains of their choice.” Talking about the reason for starting Robots Alive he says that, “Robotics and Automation has the potential to revolutionize the industrial scenario. It promises to bring the same result as computer systems have brought in services and other sectors. However, many developing nations like India, Thailand, Indonesia, Philippines are still to adopt robotics and automation in a big way. Considering the gap and opportunity coupled with our experience and understanding of the same, Robots Alive was born.” His company has clients distributed across industry segments like FMCG, Automotive and Food & Beverage. He opines that, “Robotics is best suited for industrial automation (manufacturing, packaging, assembly etc.). Most of the tasks in these sectors are dull, dirty and dangerous for human beings and as such utilizing Robotics and automation in these sectors would improve productivity, safety as well as the quality of the end product. Human operators can then take up more value added roles in the industry”

Akash Gupta & Samay Kohli, Co-founders, Grey Orange Robotics

Being passionate about Robotics since their school and college days, Samay Kohli and Akash Gupta co-founded Grey Orange Robotics based in Gurgaon after studying multiple industries and narrowing down to warehouse/logistics since it seemed poised for the most growth in the years to come and the customer pain points were quite stark. The company’s clients include Flipkart, Jabong and Datt Mediproducts. The company has build the robot “Butler”, a mobile intelligent ground vehicle used for material handling. According to the founders, an ideal team that can come up with a world class product in the Robotics industry would be one with “deep specialization in server engineering, electrical, embedded programming and mechanical engineering (with focus on design, manufacturing and materials).” Talking about the sectors that are best suited for the adoption of Robotics are those with large volumes, frequent demand spikes or are prone to frequent audits/quality checks. Also industries where the volumes are huge enough to occupy large real estate are also prime candidates for Robotics. This makes automation ideal for sectors like retail, pharma, e-commerce, automobile spares and engineering tools. Having said that, Robotics is applicable in almost all sectors that need to store, assemble and transport physical products. Incidentally, both Kohli and Gupta were part of the AcYut project team that is currently being mentored by Dr. Rout at BITS, Pilani. The AcYut project comprises of students from various disciplines and has to its credit the building of India’s first humanoid robot.

Fahad Azad, Co-founder & Managing Director of Robosoft Systems, a Mumbai-based company founded in 2008 that manufactures duct cleaning and inspection robots, DIY educational robots and UAV research platforms feels that robots can replace humans to do any monotonous, dirty or dangerous tasks in any industry. He adds that someone wishing to get into the Robotics industry must have a wide variety of skills and a thorough understanding of Systems Control along with System Integration. But he feels that those passionate about Robotics from any field of Engineering can be a part of a team working on a particular Robotics project.

Challenges in Robotics in India

Abheek Bose, CEO, Robots Alive

Among the many challenges that plague the Robotics field in India, the primary ones among them have to do with the high cost of adoption, availability of skilled talent and procurement of hardware components. Talking about these challenges, Bose says that, “the cost of adopting Robotic technology is very high due to the cost of procuring imported hardware components as well as training personnel. As Robotics is a multidisciplinary field, acquiring and retaining quality talent is a big issue. Lastly, SME customers need to see visible ROI before they proactively adopt Robotics.” Echoing a similar concern is Azad who says that the capital-intensive nature of Robotics adoption when compared to the low cost of human labour clearly tips the scale in favour of the latter.

Voicing similar concerns are the founders of Grey Orange Robotics, Kohli and Gupta who say that in general hardware businesses are challenging because of all the paperwork involved in importing hardware parts into India. They further add that there are not many commercial applications that are ready to enter the market. Like Bose, they also feel that there is a scarcity of talent that specializes in the many disciplines such as electrical, embedded, software and mechanical that make up Robotics. Importing quality components leads to longer lead times and other excise and licensing woes is also a major concern for them, in addition to finding early adopter customers of Robotics.

From an academic perspective, Dr. Rout lists some of the challenges coming in the way of Robotics in an Indian scenario –

- As Robotics is multidisciplinary in nature, barring students in the top schools in India, the others lack the knowledge required in four to five engineering disciplines to become an expert in this field. Also most of the students develop projects that already exist in the public domain.

- Scarcity of good faculty to teach the subject

- Barring a few regions in India, Robotics as a subject is not taught well to the engineering students

For businesses, like others he too blames the absence of hardware companies that can cater to them and the dependence on countries like China, USA and Europe to procure the necessary components as a major stumbling block.

Future of Robotics in India

There is no denying that Robotic technologies are all set to change the way things are done in the industries in which they are being implemented. All the entrepreneurs we spoke to voiced a similar sentiment and are clearly optimistic about the use of Robotics in various industrial segments and its future in India. Bose says that, “I see Robotics mainly capturing industries like manufacturing, pharmaceutical, FMCG, packaging and inspection. A bit of Robotics would also be seen in the healthcare sector primarily in the form of assistive and skill development technologies. The other promising sectors are defence and education.”

Kohli and Gupta have this to say about the future of Robotics in India – “We had the PC revolution, then the mobile revolution and we are now convinced that going forward it is inevitable that robotics will become an important aspect of our lives (even if it works in the background, hidden from our eyes). As with other technologies, adoption in India is usually sluggish, however, once picked up, it does follow a steeper growth trajectory. We are certain that in sectors where demand is rising, there will be huge opportunities and hence a higher rate of adoption of Robotic technology.”

Forecasting the adoption of Robotics in India in the future, Dr. Rout says that, “due to globalization and high industrialization, Robotics in India is poised for a bright future. Considering that India is already a manufacturing hub catering to the whole world, the use of robots in every aspect of manufacturing will provide the necessary edge to companies. In turn this will propel the requirement of skilled manpower for this technology.”

Fahad Azad, Co-founder & Managing Director, Robosoft Systems

Azad cites that, “as there is acute shortage of reliable blue colour labour in all industries, coming up with Robotic solutions that can solve this problem will lead to the growth of a separate Robotics sector in India.”

Advice to entrepreneurs, startups and students wishing to get into Robotics

Kohli and Gupta have a few words of wisdom for budding entrepreneurs who wish to set up a Robotics company. They advice such entrepreneurs to spend considerable time to understand a customer’s pain points. As Robotics solutions are very expensive, a through customer validation is extremely important. They add, “hire smartly and have a good team in place, not just for engineering but also for vendor management since robotic hardware comprises of a lot of components.”

“Sell first and then build!” says Bose. He believes that there are customers who are willing to trust entrepreneurs and putting faith in their abilities before they actually build a full-fledged robotic product.

Both Dr. Rout and Azad feel that only a pure love for Robotics should spur entrepreneurs to start a business in this field. They should focus on the knowledge component rather than worry about profits, valuation and acquisition. Dr. Rout says that such entrepreneurs should be able to build something that every Indian is proud of purchasing. Azad adds that, “if you can solve a problem by reducing cost, time or labour using robots, go ahead and do it.”

Conclusion

Given that Robotics is fast entering into the industrial space in India, it is but natural that a lot of employment and entrepreneurship opportunities are opening up for people who wish to enter this growing and exciting field. From what the many entrepreneurs had to say, there is no denying the fact that there are many challenges that need to be overcome before India is seen as a go-to destination for Robotics. One of the biggest challenges that they face today is the procurement of the hardware and other electronic components that are required to build a robot. However, this can be seen as a golden opportunity for budding entrepreneurs to set up businesses that can supply “Made In India” components and hardware to the existing and upcoming companies involved in Robotics. The future of Robotics in India seems certainly bright and promising!

obots in laboratory, life science and pharmaceutical applications perform tasks at rates beyond human capability. These robots function in potentially hazardous settings in proximity to biological dangers, the threat of radioactive contamination, and toxic chemotherapy compounds. Robotics are called upon to assemble and package a variety  of medical devices and implants as well as preparing prescriptions for mail-order pharmacies or hospitals.

of medical devices and implants as well as preparing prescriptions for mail-order pharmacies or hospitals.

“Robots are doing assay analysis and automating the movement of test tubes in research laboratories. Because of the high number of samples that need analysis and the amount of data collection required, the process and costs are easily validated with robotics,” says Chetan Kapoor, Chief Executive Officer of Agile Planet Inc. (Austin, Texas) “In pharmaceutical applications, hospitals use robots to mix potentially hazardous cancer drugs and those associated with radiation.”

Trends

“Laboratory automation is a growing field for robotics, from drug discovery to pharmaceutical and medical device manufacturing, to performing blood sample testing,” says James Shimano of Precise Automation Inc. (San Jose, California) “I see more interest in robotics by pharmaceutical companies for scientific research.” Robotics have considerable potential in life science applications, says Shimano. “Consumers do not directly see the impact of robotics in life science applications but robots lead to better and less expensive pharmaceuticals. Robots also dispense medications in pharmacies.”

Similarly, DENSO Robotics (Long Beach, California) finds more business in the medical and pharmaceutical markets. “We are heavily involved in manufacturing eyeglasses and a variety of other medical devices,” says out Peter Cavallo, North America Robot Sales Manager. “Biological, pharmaceutical and chemical testing are growing  areas of robotics. In the life science and pharmaceutical industries, robots play a key role in liquid handling.”

areas of robotics. In the life science and pharmaceutical industries, robots play a key role in liquid handling.”

Cavallo delineates how robots can accommodate a wide variety of products that change frequently. “Integrators use tool changers and vision to recognize and react to different parts. Robots with vision and tool changers are flexible and able to accommodate multiple configurations of items on the same production line.”

Richard Motely, Senior Account Manager at FANUC Robotics America Corp. (Rochester Hills, Michigan) says the benefits of robotics in traditional industries are replicated in the life sciences sector. “In clinical laboratories, robots are used for drug discovery and research and provide similar benefits as in other industries. These benefits include achieving higher consistency, product integrity, better record-keeping and traceability.”

Motely says robotics assist pharmaceutical manufacturers in defending against fraudulently produced and marketed medications. “The pharmaceutical industry places an increasing emphasis on traceability for product safety and defense against counterfeiters. That emphasis on tracing the manufacturing through the supply chain to the point of sale has lead pharmaceutical companies towards increased use of robotics.”

Motely explains when an over-the-counter medication is purchased, bar code scanners can determine if that product was legitimately sold. “If a bar code that should have gone to New York shows up in Michigan, the system can flag that product as counterfeit. That trend is interesting, particularly for packaging applications.”

The use of robotics to thwart counterfeit pharmaceutics is important to end-users of robots made by Adept Technology Inc. (Pleasanton, California) says Rush LaSelle, Adept’s Director of Global Sales and Marketing. “Driven by intellectual property concerns, pharmaceutical and medical device manufacturers are re-shoring, bringing production back to the United States. Off-shore pharmaceutical and medical device manufacturing is coming back and robotics act as a vehicle for re-shoring.” LaSelle says robotics help general industry manufacturing move production back to the United States, although the process is occurring more rapidly in the medical devise and pharmaceutical sectors.

Research laboratories are often located within tight quarters. To address this issue, robot makers strive to downsize their product offerings. “The trend is towards decreasing the size of the equipment. Equipment takes up a fair amount of space and laboratories are usually not very large. I see a trend towards minimizing or miniaturizing the equipment, or ‘lab on the chip’,” says Dr. Andrew Goldenberg, PhD, Chief Executive Officer and President of Engineering Services Inc. (ESI, Toronto Ontario, Canada).

The “lab on the chip” are small devices that look similar to microchips but are etched with very tiny vessels into which liquid is pumped for biological tests, expounds Goldenberg. “The ‘lab on the chip’ uses much less quantity of material as well as being physically small and portable. The small size uses precious and expensive bioassays more efficiently and facilitates field tests,” Goldenberg says. Miniaturization of equipment, transportability and minimizing quantities used is particularly important to laboratories that perform many thousands of experiments, while minimizing waste, concludes Goldenberg.

Integrated robotic systems using laboratory equipment are capable of impressive throughput. A biochemical assay can be read out in a tenth of a second per well. An entire 1,536-well microtiter plate can be analyzed in just over half a minute.

Despite high levels of general unemployment, clinical laboratories have difficulty recruiting new technicians to staff them, points out Craig Rubenstein, Life Science Technology Leader with Motoman Robotics Division of Yaskawa America Inc. (West Carrollton, Ohio) “The average age of technicians in clinical laboratories is in the 50’s. Because these technicians are rapidly reaching retirement age and few people come in to take their place, the robotics industry sees an increased adoption and acceptance of robots in laboratories. Technician work in laboratories is unglamorous because the work is done at night or early in the morning.”

Continuing, Rubenstein says, “Technician pay is okay but laboratories are generally located in windowless basements and is not an appealing environment to work in. Because of a gradual but consistent decline in the number of people trained in these positions, degree programs for these positions dried up and closed.” Without a sufficient number of new people becoming laboratory technicians, robotics help fill the void, says Rubenstein.

Related to aging technicians, the general population is aging as well, comments Rubenstein. “As the population ages, more clinical testing is ordered by physicians. Because the demand for testing is going up and the availability of human resources to do the work has been declining, robotics offer an opportunity to meet that demand.” In short, the trend in diagnostic laboratories is fewer people doing an increased amount of work with robotics helping to meet that increased demand.

Throughput and capacity are the leading justifications for end-users to invest in robotics, not elimination of labor. Laboratories would rather have scientists interpreting data the system produces rather than running the system itself.

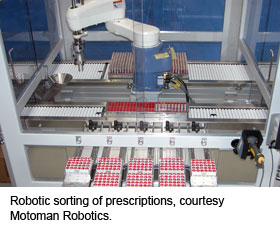

Robotic Pharmacies

Due to the potential hazards and high volumes, some hospitals and larger health care clinics utilize robotics to dispense medication. “Robotic pharmacies are expanding rapidly within hospitals and clinics. Several companies are servicing that market and the interest level will only increase,” says LaSelle. “On the retail level, robotics in local pharmacies will be a challenge. The technology is available but regulation will pace the growth of robotic pharmacies more than the technology.”

Motley has a similar outlook as LaSelle. “Robotic pharmacies have been adopted in high-volume settings, such as mail-order pharmacies and by hospital and clinics with a high patient count,” says Motley. “To make robots attractive to the local pharmacy, the robotics industry must implement another layer of cost-reduction for the overall system. Someone clever could put together a system at a reasonable cost, but robots are still only in higher volume pharmacies.”

Lab Work

Robotics play key functions in assembly and packaging of medical devices, says Agile Planet’s Kapoor. “In medical device manufacturing, robotics play an active role in assembly. The manufacturing process is highly regulated and must be approved by the Food and Drug Administration (FDA). Manufactures use robotics to reduce cost.”

Kapoor also says robotics perform important tasks in surgical procedures. “Tele-operated surgical robotics are used to augment the surgeon. Robots are used for delivery of radiation and for proton therapy. The goal is to administer the smallest dose of radiation as possible to the precise location. Robots are very precise, positioning equipment and patients accurately in three-dimensional space.”

Sylvie Algarra, Life Science Activity Manager with Stäubli Corp. (Duncan, South Carolina) says, “Robots are loading and unloading injection molding machines, assembling medical devices and polishing implants. In pharmaceutical production, robots handle bottles in the cell culture process, loading and unloading autoclaves and packaging machines, as well as de-nesting syringe tubs.”

Applied Manufacturing Technologies Inc. (AMT, Orion, Michigan) works with companies that produce dental appliances. Jordan Merhib, AMT’s Director of Business Development, describes a typical application. “A dental appliance manufacturer uses several robots primarily for sorting and packing at the end of the production line. Another company making personal medical devices and eyeglasses use robots for machine tending, loading raw materials into machines, and unloading finished product.” Merhib states that personal medical devices have many unique parts and their assembly and packaging is especially suited to robotics.

Robots help researchers perform a sufficient number of experiments to ensure valid conclusions, says Goldenberg. “A robotic micro-array can put 40,000 dots of deoxyribonucleic acid (DNA) no more than 75 microns in diameter onto a single slide. That cannot be done with a human hand. Using vision, a robot can identify an object of interest on a petri dish.”

Citing an example, Goldenberg relates that, “In cloning, robotic vision identifies what part of the colony bacteria comes from. Vision helps identify the quality of the bacteria and helps direct the robot with special tooling to move the high quality bacteria into another petri dish. Vision is used to identify what part of the colony needs removal for different processing or for disposal.”

Prognosis

Robotics have a certain future in laboratory, life science and pharmaceutical applications. “I see increased activity for bench-top robotics performing various protocols. These stations are reprogrammable and many are complex,” says Goldenberg. “Robotics are essential to modern scientific or commercial research and experimentation.”